How we work

STEEl PIPE MANUFACTURING PROCESS

The sources of our coil that we use to make steel pipes are major steel enterprises such as China Steel Corporation etc.

Electric resistance welded (ERW) pipe is manufactured by cold-forming a sheet of steel into a cylindrical shape, and then the edges of cylindrical steel sheet are forced together to form a bond without welding filler material by (High-Frequency) electric resistance welding.

After finishing pipes, we can also provide processing service like spraying zinc, weld bead scraping and ends dressing.

In the end, providing eddy current inspection, hydrostatic testing and tensile testing to customers if needed which is in our service as well.

Electric resistance welded (ERW) pipe is manufactured by cold-forming a sheet of steel into a cylindrical shape, and then the edges of cylindrical steel sheet are forced together to form a bond without welding filler material by (High-Frequency) electric resistance welding.

After finishing pipes, we can also provide processing service like spraying zinc, weld bead scraping and ends dressing.

In the end, providing eddy current inspection, hydrostatic testing and tensile testing to customers if needed which is in our service as well.

MANUFACTURING PROCESS

PRODUCTION EQUIPMENT

SLITTING LINE

We have 3 slitting machines in our company. Different materials of steel coil can be slit by them, including hot rolled steel coil, cold rolled steel coil, galvanized steel coil. The thickness range can be slit is from 0.4m to 9.0mm, and the width range is from 750mm to 1520mm.

BAND CONVEYOR

It is used to stabilize the steel belt and ensure that the steel belt can be supplied stably during the steel pipe manufacturing process.

CUTTING SAW

It cuts tubes in a specific length and make sure that all the length of tubes are what consumers want.

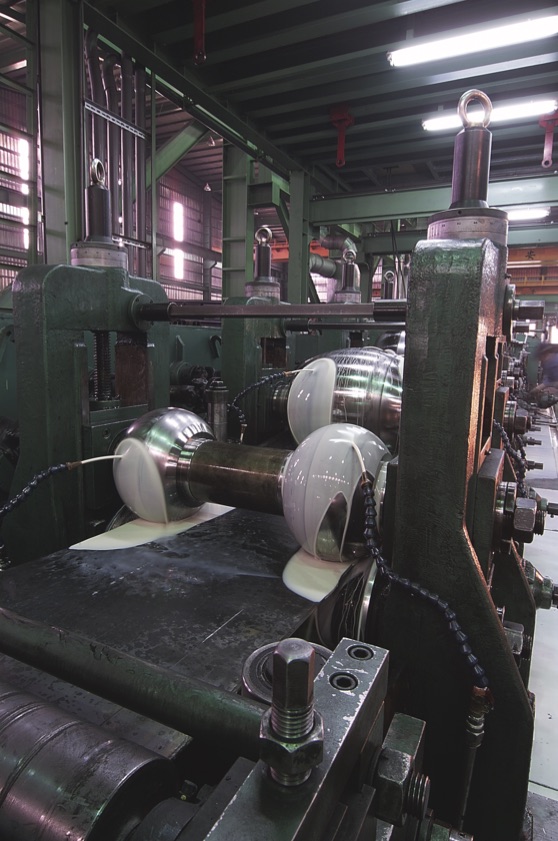

TUBE MILL

There are 10 tube making machine in our company. The maximum capability of the pipe diameter and the pipe thickness from these machines are 219mm and 9.0mm. Currently, we can provide round pipe, square pipe, oblong pipe, oval pipe, special-shaped pipe, eye-shaped pipe and so on.

PIPE PROCESS EQUIPMENT &

3D LASER CUTTING

CUTTING EQUIPMENT

In order to meet customers’ needs of short pipe, we have a cutting section to provide cutting service and pipe shrinking service.

MAZAK 3D FABRI GEAR 220 II

for Three-Dimensional Laser Steel Pipe Processing

In order to help clients to develop new products, we invested tens of millions NT dollars into MAZAK 3D FABRI GEAR 220 II for three-dimensional laser steel pipe processing, which can simplify processing step and effectively help customers save developing time and costs, so as to improve quality and promote diversity.

TRIMMING EQUIPMENT

We have trimming equipment to help customers do steel pipe end face trimming.

LABORATORY & TESTING INSTRUMENT

LABORATORY

Our laboratory can provide hardness testing, mechanical properties testing, flattening and flaring testing, crystal phase diagram testing and roundness testing.

HYDROSTATIC TESTING

In order to avoid the accident which might happen in high temperature and high-pressure environment, we provide a full range of steel tube pressure tests to ensure the safety.

EDDY CURRENT INSPECTION

According to the principle of electromagnetism, this technique is very sensitive for surface and pipeline inspection, even the insignificant cracks can be detected.